What are the major three steps in CAD CAM dentistry?

All CAD CAM dental systems have three main parts: Data acquisition, CAD for restoration design, and CAM for restoration fabrication.

Data acquisition

There are some different methods to collect CAD data. For example, intraoral scanning, contact and non-contact digitization, and CT scan or magnetic resonance imaging (MRI).

- Intraoral scanning: take a 3D virtual image of the prepared tooth and their adjacent structures.

- Contact and non-contact digitization: after producing the model, the conventional impression will be taken. And the data will be transferred to CAD through contact digitization. Non-contact digitization, such as laser light, charged-coupled devices, and optics.

- CT scan or MRI: computed tomography and MRI are more advanced techniques for collecting data. CT data can be used in the hard tissue model like the bone, while MRI data can be used in the model of soft tissues.

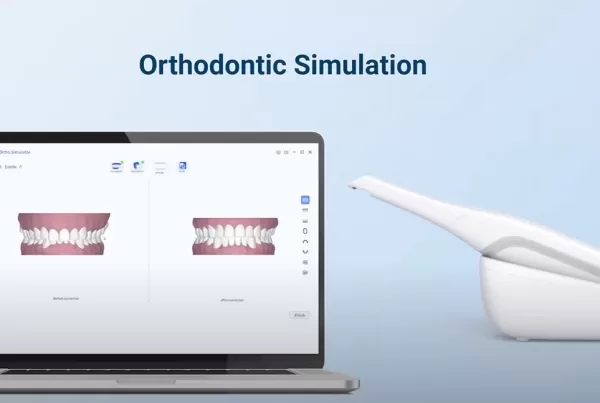

Restoration Design

Several CAD software programs are available commercially for designing virtual 3D dental restorations on a computer screen. When the design of the restoration is complete, the CAD software transforms the virtual model into a specific set of commands. Then these commands drive the CAM unit to manufacture the designed restoration.

Restoration Fabrication

CAM technology in dentistry can be classified as either “Subtractive” or “Additive” manufacturing methods.

“Subtractive” method: material is subtracted from a block to leave the desired shaped part (the restoration).

“Additive” method: the system adds material layer by layer along a designed path until the complex part is complete.