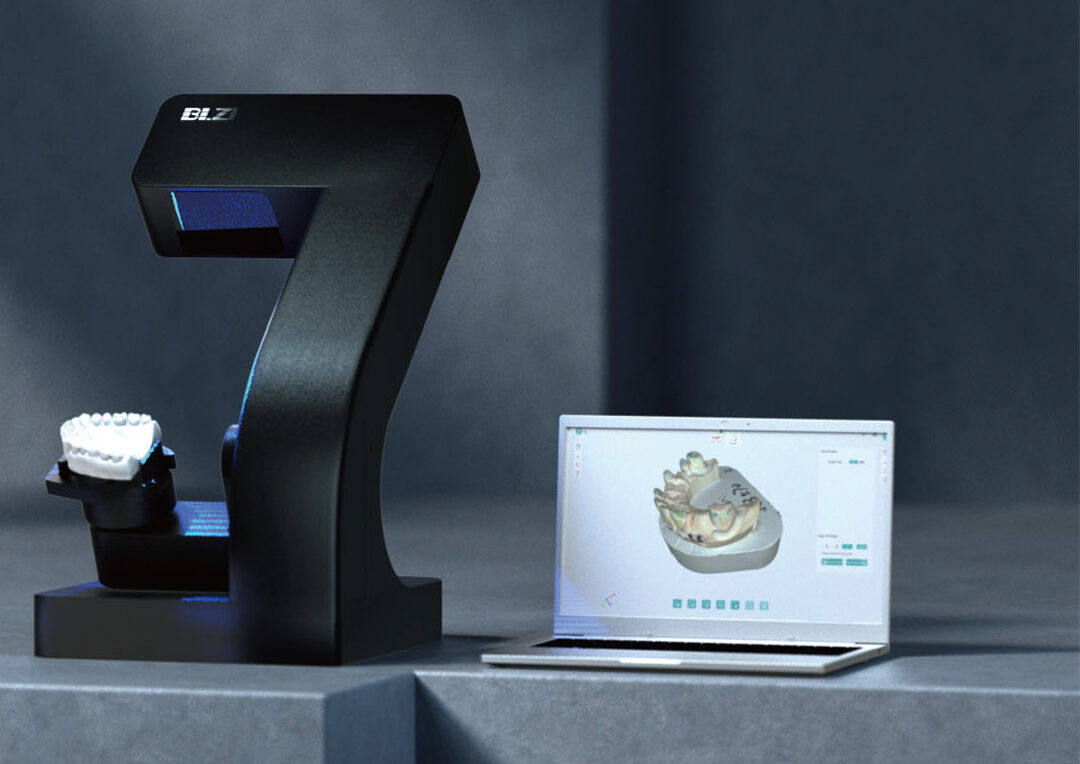

Although with each passing year, more and more labs are transitioning to digital dental labs, classical craftsmanship will continue to be indispensable in dental technology in the long term. However, as an experienced dental technician, you can use digital workflow to improve your manual skills and enhance the accuracy of your practices. After reading this article, you will learn about the benefits of a clever partnership between CAD/CAM and conventional methods.

Combine traditional craftsmanship with CAD/CAM

It’s not an either/or situation when it comes to traditional techniques and CAD/CAM. Some dental technicians are terrified of the moment when they must make the challenging choice between analog and digital. However, because both are feasible when combined, there is no need to make an either/or decision. Dental technology such as CAD and CAM, will not completely replace traditional craftsmanship, which includes dental technical skills and knowledge. Therefore, even if you are an experienced dental technician who appreciates quality craftsmanship, you can also digitize some processes and benefit from the advantages.

Two essential advantages

There are essentially two very clear advantages that a combination of analog and digital can provide you with in your everyday routine.

-

More processing safety

The traditional press technique involves many finely detailed working steps. It is a high-risk procedure in which errors can easily occur. And it requires a lot of skill and time. However, the press and CAD/CAM technology can complement each other perfectly. The restoration can be milled efficiently and precisely with the relevant wax, precisely matched to the press indication. The digital wax-up is a particular advantage. Because there is no wax distortion and the risk of an inaccurate fit is therefore eliminated.

-

Reproducibility

For example in casting, digital process can save you the time-consuming task of waxing-up the framework pattern by hand. In particular, with larger frameworks such as multi-unit bridges, it takes a relatively long time to wax-up the object by hand. So it is better to design the wax framework on the computer and mill the CAD design directly in wax. If something goes wrong during casting, you can quickly re-mill the exact same wax object by simply pressing a button. This way you can avoid the risk of having to start the work again from the beginning.

CAD/CAM is a worthwhile investment. Let’s take advantage of the possibilities provided by digital technology in everyday laboratory routines.