Do you ever wonder if your dental laboratory is well equipped? Are you prepared to fulfill the demands of the present and future?

Dental laboratory equipment includes the entire range of systems used in the fabrication of dental prostheses. Whether your lab is focused on using the latest digital dentistry technologies or traditional approaches, these systems will be important to your capacity to produce dental restorations. Having the proper equipment and keeping it in good condition is crucial to the functioning and success of your lab.

What types of equipment is needed for digital dental lab?

-

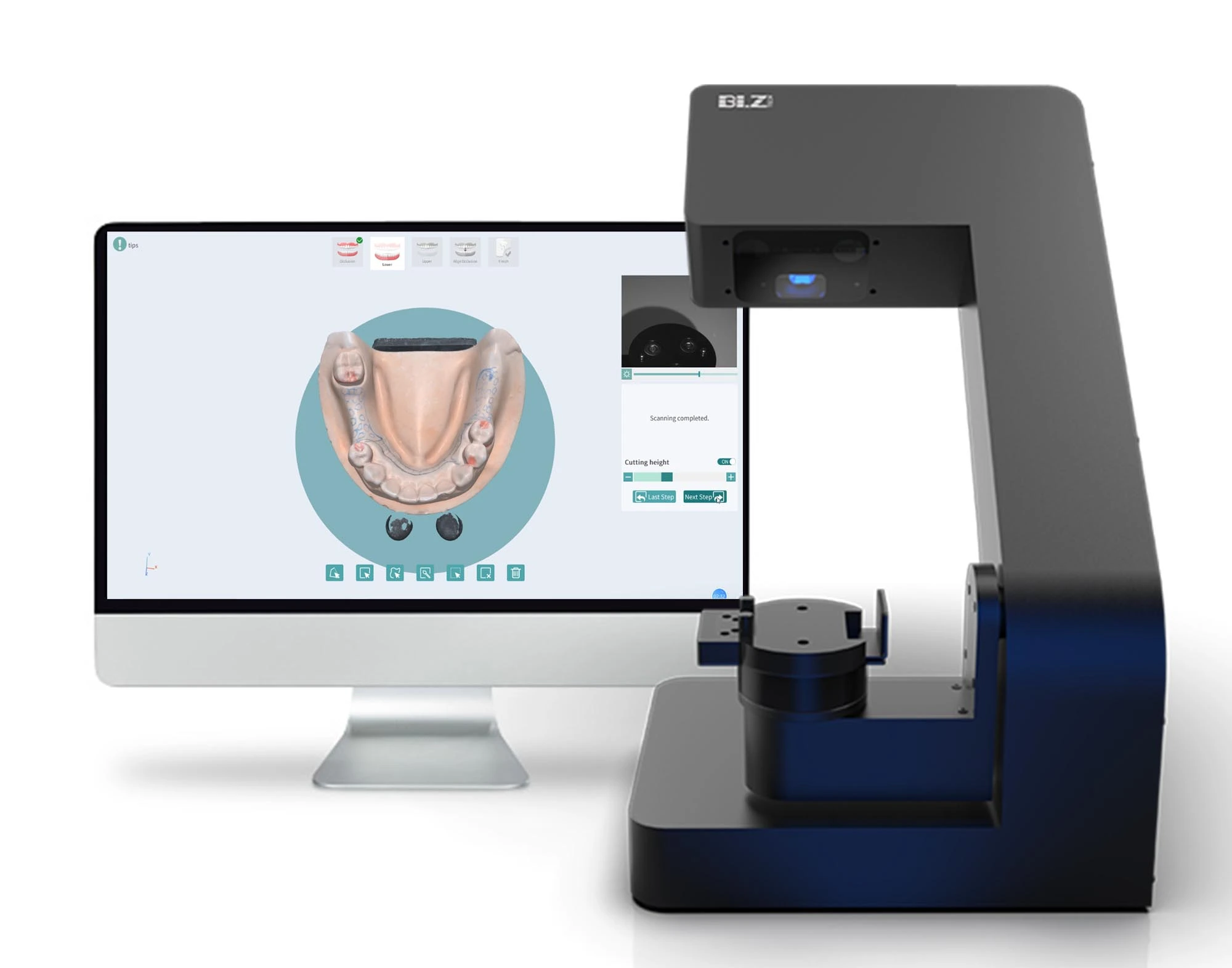

Dental lab scanner

The dental lab scanner serves as the starting point for the majority of digital dental lab workflows. While numerous imaging methods can be used, all dental lab scanners are designed to build a 3D digital model based on either a physical dental model or impression.

There are several features to consider when selecting a lab scanner that is the best fit for your lab. It includes the scan speed and scanner capacity. Furthermore, ensure that the scanner and its software are compatible with the mill, 3D printer. Or other production workflows you intend to use.

-

CAD/CAM software

CAD/CAM software is the true powerhouse of a digital dentistry lab. It is used to design a dental restoration in 3D digital model and then provide instructions to a mill or 3D printer on how to make it. Dental lab CAD software guides technicians through the process of creating a 3D digital model. Dental lab CAM software is the bridge between the computer and a mill or 3D printer and manages how materials are used.

When selecting CAD/CAM software for your dental lab, make sure it is compatible with existing hardware and software, and that it comes with proper training, support, and upgradability.

-

Milling/Manufacturing machine

Dental lab milling machine is the production workhorse of dental CAD/CAM systems. It is used to fabricate complete or partial dental restorations based on digital designs. Dental mills are designed to cut crowns, bridges, copings, frameworks, implant abutments, and more from materials such as ceramics, zirconia, alloys or wax.

When choosing a mill it’s important to evaluate how many cases it will need to handle. Because mills come in a range of sizes designed for different production capacities. You also need to know what software can power the mill. Is it compatible with the technology you use for scanning and designing? Different mills are capable of working with different materials, make sure your choice of milling machine is capable of working with the materials you prefer.